A flexographic print is made by creating a positive mirrored master of the required image as a 3D

relief in a rubber or polymer material.

Flexographic plates can be created with analog and digital platemaking processes. The image areas

are raised above the non-image areas on the rubber or polymer plate. The ink is transferred from

the ink roll which is partially immersed in the ink tank. Then it transfers to the anilox or

ceramic roll or meter roll whose texture holds a specific amount of ink since it is covered with

thousands of small wells or cups that enable it to meter ink to the printing plate in a uniform

thickness evenly and quickly the number of cells per linear inch can vary according to the type

of print job and the quality required.

Flexographic labels can work with many label sizes, shapes and printing techniques making it

an ideal labeling solution for many projects. Whether you need 100 or 10,000 custom labels on

each roll, we can fulfill your specific needs.

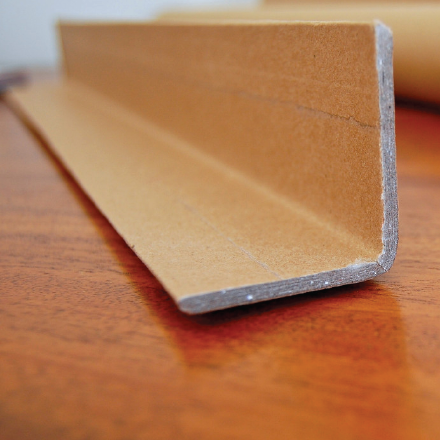

Our range of packaging corners protection is one of the most extensive available in our region,

with strong, affordable protectors made from cardboard, and even better news is that it´s also one

of the best value and most flexible ranges.

Our packaging corners protectors can safeguard, stabilize and reinforce palletized loads in

transit and storage. They’re also used to provide additional protection inside and outside of

cartons. Made from compressed recycled material, edge protectors provide an economical and

environmentally friendly method of improving stability.

A plastic bag, polybag, is a type of container made of thin, flexible, plastic film, nonwoven

fabric, or plastic textile. Plastic bags are used for containing and transporting goods such as

foods, produce, powders, chemicals, and waste. It is a common form of packaging.

We can meet any custom requirements by putting your company logo and message on all products.

Contact us to discuss your requirements and find out if we can help you to build your brand

with custom printed poly bags.